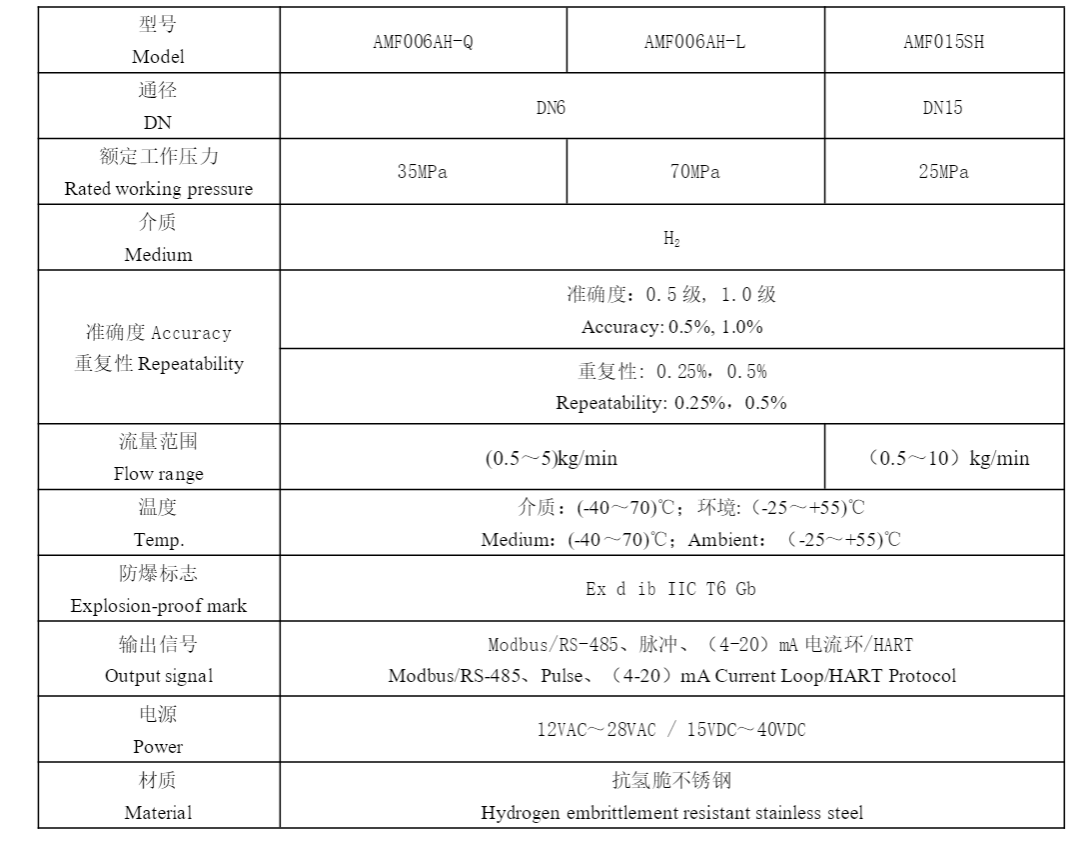

AMF015SH

AMF015SH

Coriolis Mass Flowmeter is applied for precision measurement in the fields of CNG, LNG, Petrochemical, New energy, Automotive, Smelting industry, Paper and pulp, Environmental monitoring, Cryogenic and etc. Its function is for trade settlement and process

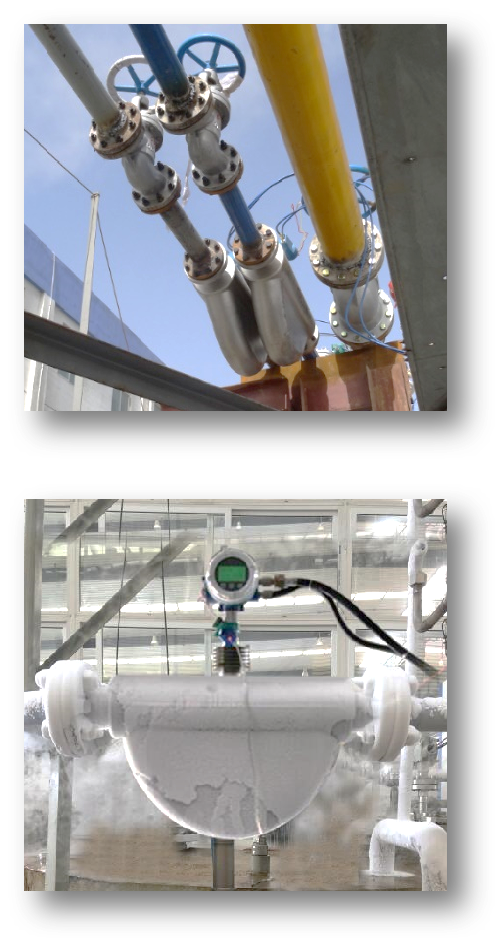

ANDISOON excels in measuring under challenging conditions, including high pressure, high viscosity, and high and low temperatures. When measuring CNG (compressed natural gas), the difficulty lies in the high pressure. However, ANDISOON's sensors can withstand high pressures, allowing the necessary increase in flow tube thickness, allowing the transmitter to detect signals with greater sensitivity. Therefore, ANDISOON's mass flow meters specially designed for CNG gas dispensers have been widely used in the market.

Product Features

1. Using hardware DSP data processing technology Our company adopts the world's most advanced second-generation transmitter technology - DSP processing technology, which has higher measurement accuracy, wider range, simpler structure and more stable operation.

2. Can measure high pressure gas The application of domestic mass flow meters is mainly concentrated in the field of liquid measurement, and there is no mature application in the field of gas measurement. On the basis of mastering DSP processing technology, our company complies with the needs of the industry and designs a high-precision mass flow meter suitable for high-pressure gas measurement, which is more suitable for the needs of the high-pressure gas measurement industry and has better performance.

3. Industry-leading high-pressure aging process The high-pressure aging platform built by our company conducts aging tests on each CNG flow meter, providing an effective solution to the problem of measurement performance degradation that may be caused by changes in sensor characteristics due to long-term high pressure during later use.

4. Good zero point stability Our company has designed a set of high-precision processing technology for the manufacturing of sensors to ensure the quality of the sensor, and its zero-point stability is not inferior to imported products.

5. Multi-parameter measurement technology Our company adopts digital signal processing (DSP) technology. Compared with analog technology, front-end digital processing equipment significantly reduces signal noise and responds faster. It adopts 485 communication. The host side of the metering system can obtain the required relevant parameters through 485 communication. , such as: mass flow, volume flow, temperature, density, status and other information. For liquid applications, mass flow meters using multi-parameter measurement technology can achieve an accuracy of 0.2. The actual accuracy can be higher and the performance can be even better.

6. Self-diagnosis technology In the actual application process, when an abnormality occurs in the flow meter, the fault code can be read through debugging software or handheld debugging equipment, which facilitates flow meter users to solve the problem more comprehensively and eliminate faults.

7. Supports standard industrial control communication protocols ModbusRTU, etc., making it easy to configure and use. 8. Industry-leading cryogenic calibration platform In the process of LNG development, the company has built an industry-leading cryogenic calibration platform, using liquid nitrogen (-196°C) with a lower temperature than LNG as the calibration medium, providing a cryogenic solution for the development of LNG Coriolis flowmeters. Application experience. This calibration platform has now been used as the calibration platform for all the company's LNG flow meters, enabling real cryogenic calibration of each LNG flow meter to ensure the measurement accuracy of cryogenic applications. 9. Good scalability The company can design and manufacture mass flow meters with special specifications and models and special functions according to user needs, tailor-made for users.

| Accuracy | 0.1% (Optional), 0.15%, 0.2%, 0.5% (Default) |

| Repeatability | 0.05% (Optional), 0.075%, 0.1%, 025%(Default) |

| Density | ±0.001g/cm3 |

| Wetting the liquid material | 304 , 316L, ( Customizable: Monel 400, Hastelloy C22 , etc.) |

| Temp. | ±1°C |

| Measuring medium | Gas, Liquid and Multi-phase flow |

PREV:AMF006AH

NEXT:That's the last one